(C) G. Forrest Cook 2002

Solar Circuit Kits are available from CirKits.

|

|

|

|

| Solar Charge Controller | Dark Activated Switch | Low Voltage Disconnect | Battery Voltage Monitor |

(Photo 1) Solar furnace mounted on an external door |

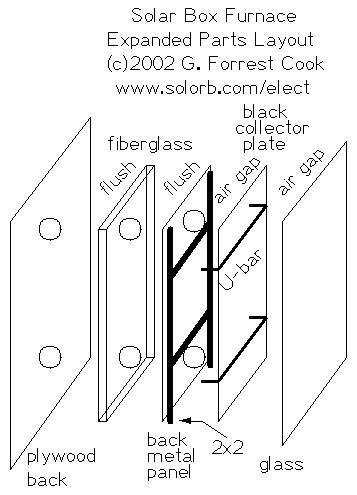

(Figure 1) Expanded parts layout |

(Photo 2) The fan pushes cold air into the input port on the bottom. |

(Photo 3) Warm air exits from the output port on the top |

(Photo 4) West-facing solar box furnace installed on a small shed. |

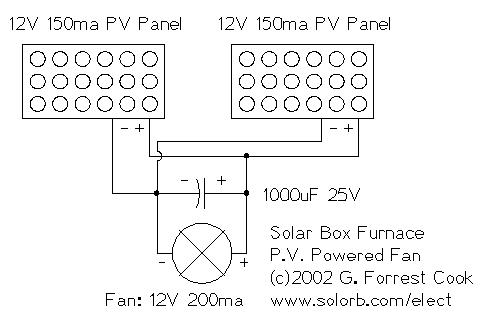

(Figure 2) Schematic

This project involves the construction of a self-contained solar box furnace (Photo 1). It is suitable for heating up a small room or a detached shed. I use the furnace to warm up my garage, it takes the chill out of a fairly large space on cold sunny days. The furnace was in use on it's initial location for over 10 years before being moved to a small shed in the Colorado mountains. The only maintenance involves occasionally vacuuming the dust from the bottom of the box and cleaning the glass.

I assembled the furnace out of materials that I had laying around my workshop. A larger version of this device could be built to add supplemental heat to a house or other large building. The price of natural gas and heating oil is continually rising, this furnace can be used to lessen the use of expensive sources of energy. For the best results, the heated space should be well insulated before adding the solar heat collector.

Nominal Operating Voltage: 12VDC

Operating Current: 200ma (depending on the fan)

Heat Output: depending on the size of the box, the equivalent

of a few hundred watts when the box is in full sun.

Some example data was taken with the solar furnace. On a sunny day with a 10 degree C outdoor temperature, the furnace was able to increase the interior garage air from 12 degrees C to 29 degrees C. The fan's air flow rating is 30 cubic feet per minute at full speed.

This is a self-contained and self-powered device. Sun shining on black metal collector plate is absorbed and converted to heat. Sun shining on the solar panel array powers the fan, which pushes cold air into the bottom of the box (Photo 2). The cold air warms up as it passes over the collector plate, then the warmed air exits from the top of the box (Photo 3). The insulation at the back of the box prevents heat loss through the cold side, which is useful if the furnace is mounted away from the heated space.

The electronics in this project are quite simple (Figure 2). The solar panel array provides enough current to run a 12V computer fan. The capacitor smooths out the electrical supply to the fan, so that interruptions in the light source don't produce sudden motor speed changes. This should increase the life of the fan bearings. When there is enough sunlight to heat the box, there is generally also enough sunlight to run the fan. No electrical controls are necessary.

A more advanced fan control system offers some advantages over a simple PV/fan combination. A differential temperature controller will insure that the fan only runs when the furnace is producing useful heat, and the fan will always run at full speed. Another advantage of such as system is that the controller can be set to turn on when the box air temperature is somewhat warmer than the room air. This allows the furnace to output air that is noticeably warmer than the room air.

A differential fan control system can be built using my differential temperature controller circuit and a source of 12V DC power. A solar-charged 12V DC solar power supply can be made with a PV panel, a 12V battery and a PV charge controller like my SCC3 design (kits are available).

The dimensions of the solar box furnace depend on the space that you have to mount the box and the materials that you have on hand. The box shown in the photos is approximately 2.5' x 4'. More collector surface will produce more heat.

Construct a wood box out of the 2x6 lumber, I used a table saw to cut 3/8" deep dado slots near the front edge of the 2x6 box sides. This produced a gap for the glass panel to slide into. Paint the 2x6 pieces with waterproof sealer such as Sikkens, polyurethane or Thompson's waterseal. Be sure to let the paint dry before assembling. Screw three of the 2x6 pieces together, slide the glass into the slots and screw the top 2x6 piece onto the lower part of the box.

A surplus shower door makes an excellent glass panel since it comes with an aluminum frame and is made of tempered glass. The shower door could be screwed directly to the front of the 2x6 box and sealed in place with silicone caulk. Glass with low iron content (solar glass) passes through more heat than conventional tempered glass, but it may be expensive or hard to find.

A surplus (and even leaky) solar hot water collector makes a good platform for conversion to a hot-air collector. These can be found for reasonable prices at recycled building material sites such as a Habitat for Humanity ReStore. Just be sure to clean out and seal any fiberglass remnants and patch any plumbing holes in the collector.

Cut the collector plate so that it fits inside of the box. I used heavy gauge corrugated steel for my collector, it can be cut with a composite diamond blade in a circular saw. Be sure to file the sharp edges of the plate smooth with a metal file. The collector plate should be approximately 2" shorter than the interior of the box so that air can pass over the bottom and top. (Figure 1) The plate should be painted flat black, high temperature stove paint is a good choice. Paint both sides of the collector plate for best results, let it dry before assembly to prevent fogging of the glass.

Bend the two metal bars into a squared U shape, they should hold the metal collector plate inside of the box so that the collector has an air gap on both the front and back sides. The U bars should fit snugly into the sides of the box. I placed the bar in a vise and hammered both ends to a 90 degree bend. Drill four 5/64" holes in each bar, 2 holes for connecting to the collector plate, and 2 holes for screwing the bar into the inside of the 2x6 frame. The collector plate is attached to the U bars with 4 sheet metal screws. The U bars are attached to the inside of the 2x6 box with 4 wood screws. The bars I used were made of galvanized soft iron, they were originally used to join sections of chain-link fence together.

A 2x2 frame should be made in a double H shape (Figure 1), its purpose is to act as a spacer between the back metal panel and the collector plate. Screw the 2x2 frame to the inside of the 2x6 box. In my prototype version, the 2x2 frame was narrower than the box so that it fit within the bent ends of the U bars.

Cut the back metal panel so that it fits exactly inside of the 2x6 box. Galvanized duct metal is a good choice of material for this piece. Using a jig saw, cut holes in the top and bottom center of the back metal panel for the ducts to pass through. Screw the back metal panel to back of the 2x2 frame.

The fiberglass insulation is the stabilized blue/green type that is used for furnace filters. Regular fiberglass insulation (pink or yellow) is harmful to the lungs and should not be used. Cut the insulation material to fit between the back metal panel and the back of the 2x6 box. Cut holes in the insulation for the two ducts. If you use fiberglass insulation, it should be completely sealed from the air path using high temperature silicone caulk.

A different type of solid insulation such as styrofoam could be substituted, styrofoam may eventually break down from the constant heat. If the solar box furnace can be mounted directly on the wall of the space that you intend to heat, the insulation may not be required at all.

Cut the plywood back panel so that it covers the back of the 2x6 box. Cut holes for the 2 ducts in the back panel.

Apply a bead of silicone caulk around the edge of the glass panel to keep water and cold air from leaking into the box.

Install the 2 metal ducts into the holes in the back of the box. The ducts should go into the box as far as the back metal panel. Mount the 12V fan to the back of the bottom duct. The duct can be cut lengthwise with a tin snip, about 1" deep. The resulting metal tabs should be spread out and drilled to match the fan mounting holes. Mount the fan on the end of the duct.

Routing of the ducts is specific to your installation. I mounted the box on an exterior wooden door and cut holes in the door for the ducts to pass through. Insulated ducts should be used if they have to pass through a cool area.

Mount the solar panels to the top of the box, or somewhere that receives a lot of sun through the day. The panels that I used were surplus amorphous type, I glued them to a fiber board panel with silicone rubber caulk, and mounted the panel on the top of the furnace box.

A commonly available VW/Audi battery maintainer solar panel is also suitable for use in this project. These panels are available on eBay for around $20, one or two of them would work nicely for this project.

Wire the solar panels in parallel with each other, the fan, and the capacitor. All positive leads connect together, all negative leads connect together. Fasten the wire junctions with two wire nuts or crimp the connections together.

Point the furnace to the South, assuming you live in a Northern climate. If you can, mount the box at an angle so that it faces directly toward the sun at noon during the winter months. In some cases, mounting the box vertically is the only option. Useful heat will be produced as long as the box receives direct sunlight during some part of the day.

In my installation, the box is mounted vertically on the back of a door and is pointed toward the South West. The furnace starts up later in the day than it would if it were pointed due South, but it warms up quickly and provides more heat later in the day. If the box is mounted on an East-facing wall, it can be used to warm up a space when the morning sun shines.

Just let it run, if the sun shines on the box, warm air will flow out of the top duct. I have used the furnace to warm my garage through several cold seasons, it nicely warms up an otherwise frigid part of the house. This box can pay for itself over time by lowering your utility bills and increasing comfort.

At night, the solar furnace may cause some heat loss due to downward convection of cold air through the box. This convection can be greatly reduced by bringing the input port up to the level of the output port with some additional ducting. A U shaped air passage will cause cold air to become trapped in the the bottom of the box at night.

During the summer months when additional heat is not desired, the glass front of the solar furnace should be covered with a reflective surface such as a piece of plywood or metal that has been painted white. The the fan can be disconnected with a switch to save bearing life.

2x 12V/150ma amorphous or polysilicon solar panels 1x 12VDC 4" computer fan, approximately 200ma operating current 1x fan finger guard (optional, but recommended) 1x 1000uF 25V electrolytic capacitor, 105 degree high temperature type 2x wire nuts 10 feet of #20 stranded hookup wire 1x clear glass pane, 3/8" tempered glass is recommended 2x6 lumber for the box frame 2x2 lumber for the internal spacer frame plywood or press-board for the back Corrugated steel roofing material 2 pieces of 1/8" x 1/2" soft steel bar, galvanized chain-link fence spacers work well flat black paint for the metal collector panel, high temperature paint is best deck type water seal for the wood pieces 1 tube of silicone caulk fiberglass or high temperature solid insulation 2x 8" lengths of 4" diameter metal ducting miscellaneous screws

The mechanical parts can be purchased from a local hardware/building supply store. Companies selling PV panels can be found on the CirKits Links to Alternative Energy Sites page.

Back to FC's Solar Circuits page.